Fork & Good started as a conversation between a scientist and a farmer…

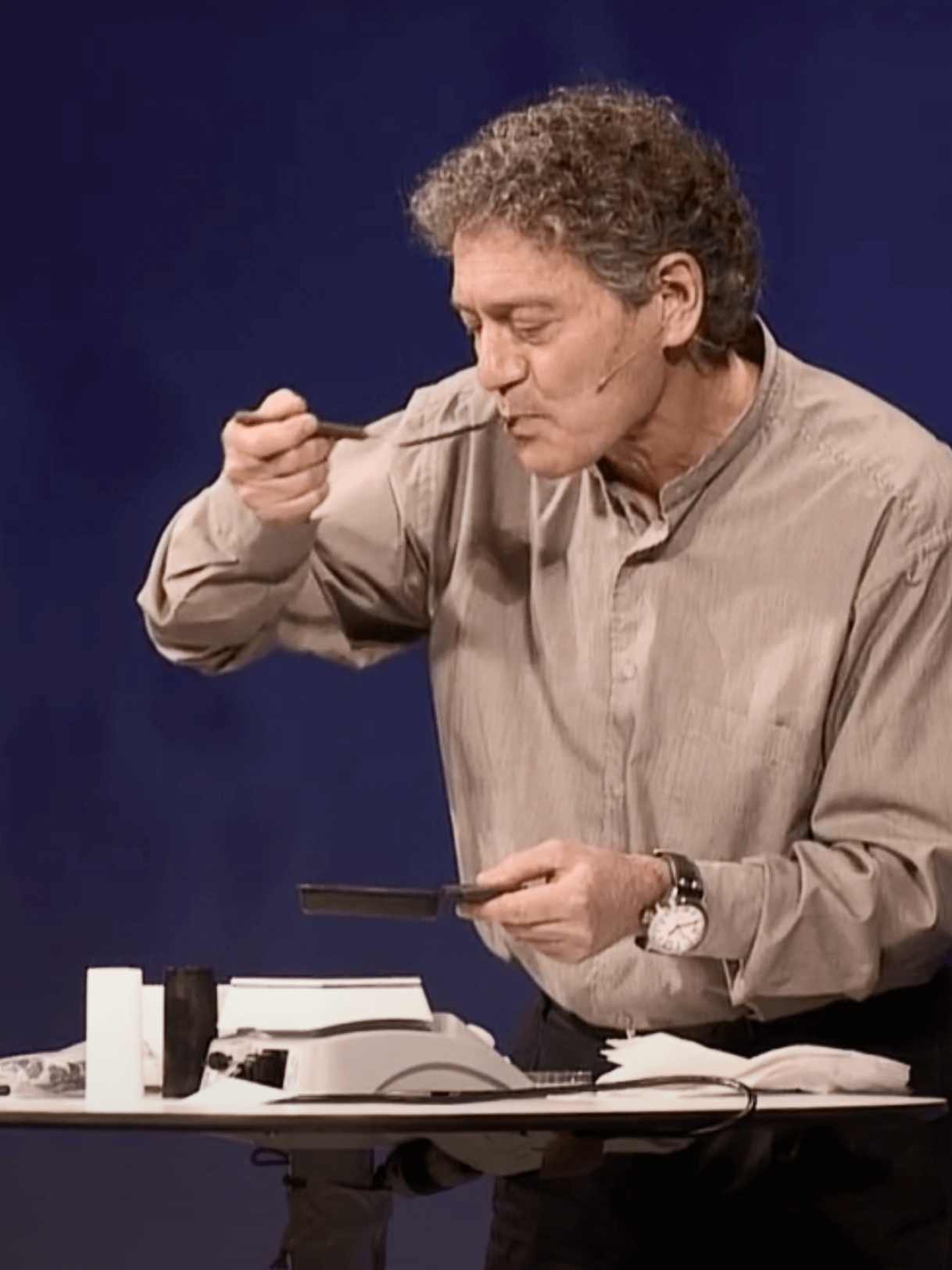

THE SCIENTIST

In 2011, our Chief Scientific Officer and co-founder Gabor Forgacs invented a technology with the potential to change meat production forever. After presenting – and eating – the world’s first cultivated meat prototype on the TED stage, Gabor, whose prior company pioneered the concept of 3D bioprinting, assembled some of the top scientists in the world to tackle the problem of manufacturing a scalable supply of real meat from cells.

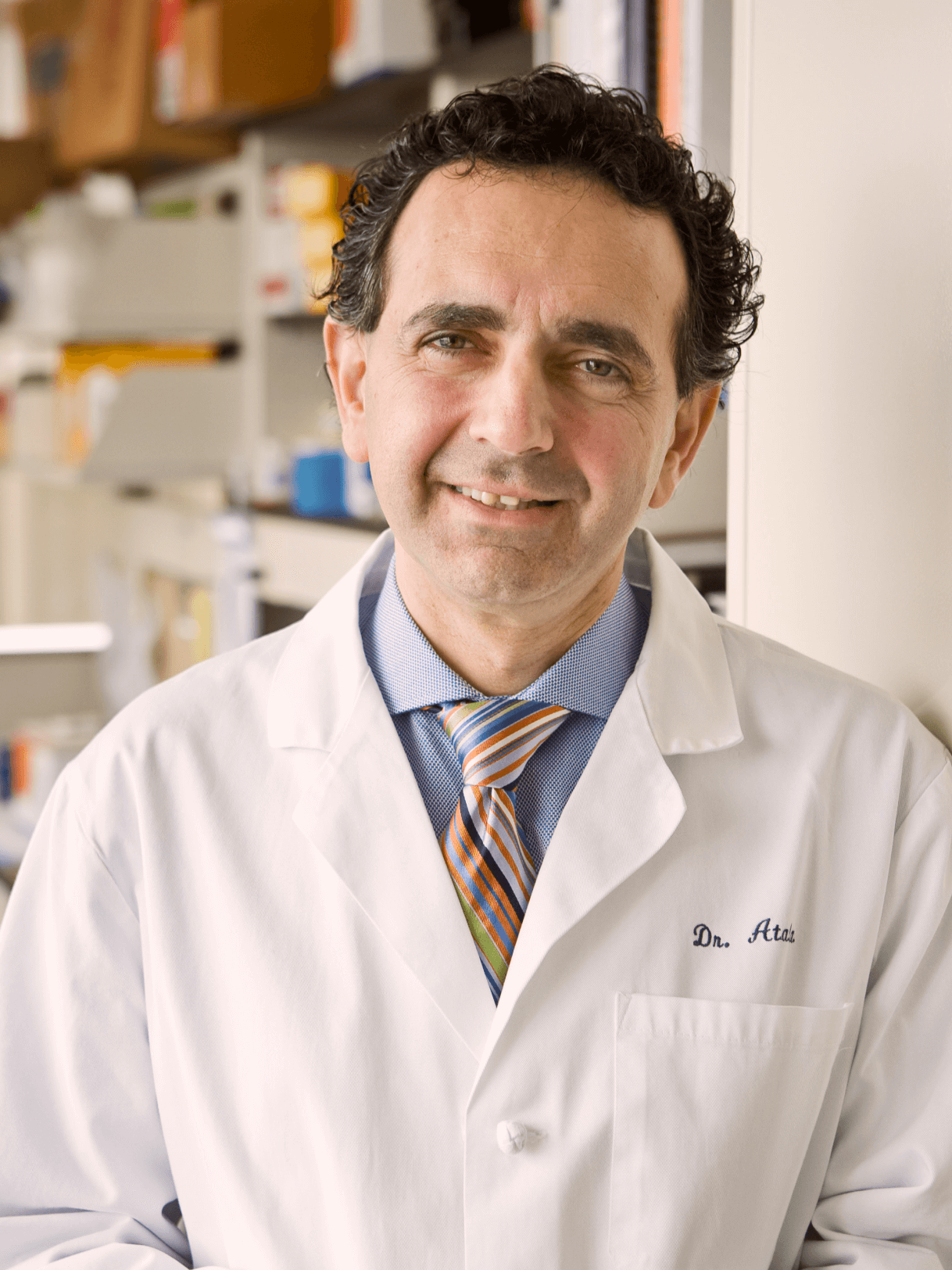

THE BOTTLENECK

Along with his partner and son Andras, Gabor made incredible advances in the field, but paused their work on food when they hit a cost barrier—the product would not be commercially viable at a cost of hundreds of dollars a pound. The company shifted its primary focus to materials, but they didn’t give up on their dream of bringing cultivated meat to the world. They approached Gabor’s long-time colleague Anthony Atala, the Director of the Wake Forest Institute of Regenerative Medicine, to leverage his expertise in tissue engineering as they continued to hunt for a solution.

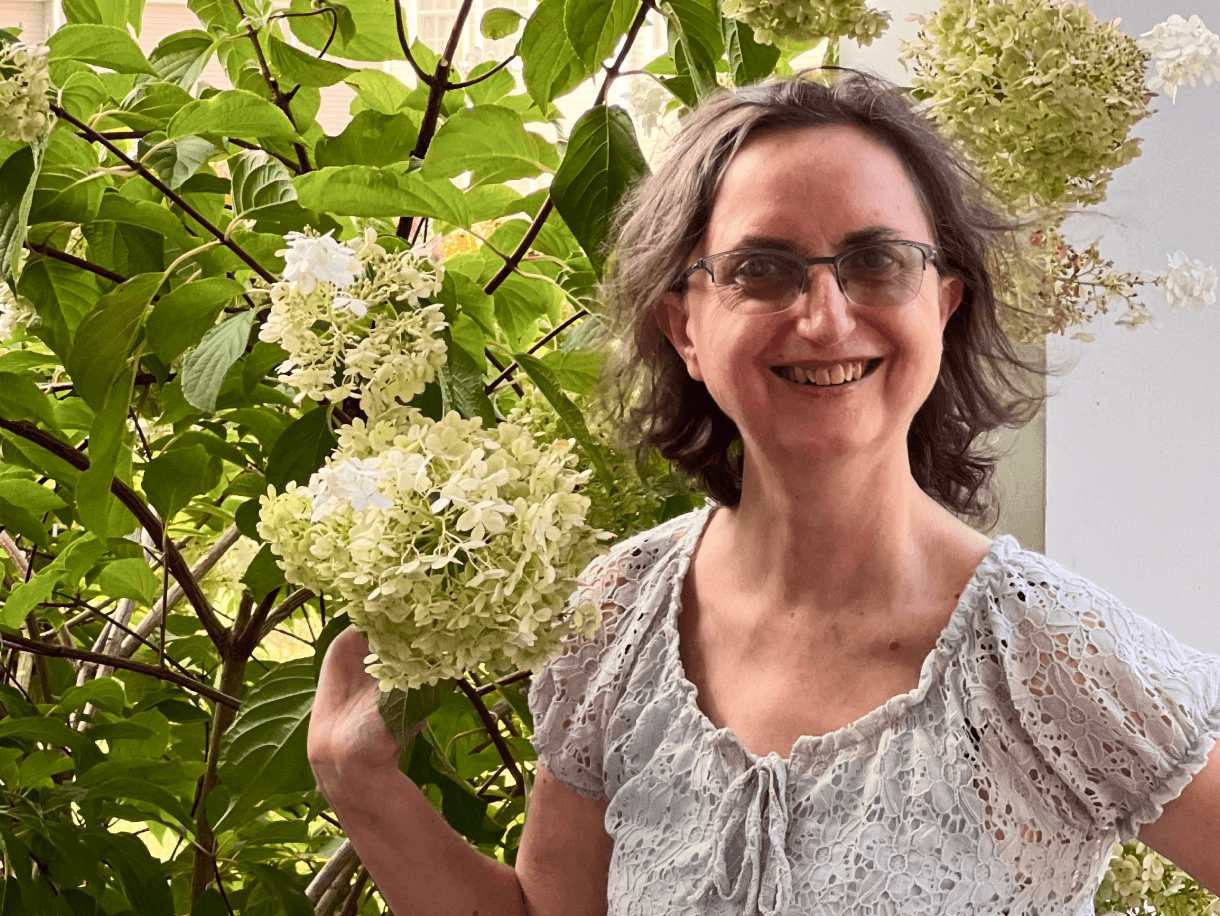

THE FARMER

When Gabor met Niya, she was the CEO of ComCrop, a Singapore-based company using hydroponics to grow vegetables in the middle of cities. Access to high quality fresh produce in urban environments is scarce, and 50% is wasted in transit— having the ability to grow vegetables on rooftops without soil and pesticides could solve that. To be successful, though, the key problem to overcome is density: grow as many leafy greens and herbs in as small an area as possible.

THE LIGHTBULB MOMENT

As Niya learned more, she realized that the field of cultivated meat was a lot like hydroponic farming — instead of vegetables without soil, it was meat without the animal. Her wheels started turning, and she realized that applying the same approaches she had honed in urban farming could be extremely relevant for the success of creating pork without the pig, or beef without the cow. Profitability wasn’t about doing tissue engineering much bigger; it was about solving the same density problem— more meat with less feedstock in less space.

THE INNOVATION: A HYDROPONIC SYSTEM FOR MEAT

Within a year of beginning their collaboration, Gabor and Niya innovated on a new technique to build a high yielding “hydroponic system” for meat, integrating powerful concepts both from cell biology and farming, and shortly after received the first patent in the cultivated meat space to do just that. Since then, they have gone on to raise funding from top investors and secure partnerships with leading food companies as they march toward their vision of scalable, sustainable, humane and cost-effective future for meat.

THE SCIENTIST

In 2011, our Chief Scientific Officer and co-founder Gabor Forgacs invented a technology with the potential to change meat production forever. After presenting – and eating – the world’s first cultivated meat prototype on the TED stage, Gabor, whose prior company pioneered the concept of 3D bioprinting, assembled some of the top scientists in the world to tackle the problem of manufacturing a scalable supply of real meat from cells.

THE BOTTLENECK

Along with his partner and son Andras, Gabor made incredible advances in the field, but paused their work on food when they hit a cost barrier—the product would not be commercially viable at a cost of hundreds of dollars a pound. The company shifted its primary focus to materials, but they didn’t give up on their dream of bringing cultivated meat to the world. They approached Gabor’s long-time colleague Anthony Atala, the Director of the Wake Forest Institute of Regenerative Medicine, to leverage his expertise in tissue engineering as they continued to hunt for a solution.

THE FARMER

When Gabor met Niya, she was the CEO of ComCrop, a Singapore-based company using hydroponics to grow vegetables in the middle of cities. Access to high quality fresh produce in urban environments is scarce, and 50% is wasted in transit— having the ability to grow vegetables on rooftops without soil and pesticides could solve that. To be successful, though, the key problem to overcome is density: grow as many leafy greens and herbs in as small an area as possible.

THE LIGHTBULB MOMENT

As Niya learned more, she realized that the field of cultivated meat was a lot like hydroponic farming — instead of vegetables without soil, it was meat without the animal. Her wheels started turning, and she realized that applying the same approaches she had honed in urban farming could be extremely relevant for the success of creating pork without the pig, or beef without the cow. Profitability wasn’t about doing tissue engineering much bigger; it was about solving the same density problem— more meat with less feedstock in less space.

THE INNOVATION: A HYDROPONIC SYSTEM FOR MEAT

Within a year of beginning their collaboration, Gabor and Niya innovated on a new technique to build a high yielding “hydroponic system” for meat, integrating powerful concepts both from cell biology and farming, and shortly after received the first patent in the cultivated meat space to do just that. Since then, they have gone on to raise funding from top investors and secure partnerships with leading food companies as they march toward their vision of scalable, sustainable, humane and cost-effective future for meat.

team culture

You never feel judged for any idea that you have so you can think really far out there without fear that it will be thought of as weird or bad. It creates a safety net that permits innovative thinking.

David, Bioprocess

At Fork & Good, we strive to create an environment where everyone is heard and respected. We do have very specific milestones but there’s always an openness to new ideas to solve problems

Bryan, Cell Line

At F&G values are practiced, not just professed. The culture of the company is almost more important than what we are trying to do and this is the foundation to having a good team that will stick together

Fran, Media

There is one shared mission here that we all care deeply about, and we are all willing to do whatever is necessary to achieve it. The mission goes beyond a common goal– it’s a huge problem that everyone on the team cares about on a visceral level

Sacha, Business

I love the collaborative atmosphere at Fork & Good. Everyone works together to build each other up. There are no dumb questions ….and someone’s always got your back if you need help

Aidan, Analytics

good nurtured meat for good natured people

join our team

Are you excited about the future of meat? We're always looking for talented people who will be the farmers of tomorrow.